Differences of Huayun hose pump from others

More Compact Structure

In modern automated production lines, the pipeline system usually is very

complex, therefore the occupied volume and land for single equipment of the

lines is very limited.Unlike most hose pumps using horizontal planetary cycloid

reducer in the market, our IHPG series

mining peristaltic pump creatively used high-performance

vertical transmission gear reducer, meanwhile the pumps were assisted with

One Button to Change forward/reversal

In many occasions, we need to transport materials between two points. If using other

types of pump, we need two set of pumps with two sets of pipe. In this situation, with

the ability of double rotation directions (forward/reversal), a Chemical application peristaltic pump is

With Leak Detector

Since the life of special hoses of a

concrete application peristaltic pump

No need of lubricant

In current market, there is lubricant in most peristaltic hose pumps. The life of

hoses can be extended by this way, but it might causes four problems:

1. 1) Once the hose reaches its life limit, the lubricant will come into the

hose via the crack on hose, and then contaminate the pumped liquid

2. 2) In many applications, peristaltic hose pumps are used to for

pumping toxic material. While replacing the hose, it is required to

release the inside lubricant at first. This might contaminate the

environment, since there might be toxic material mixed with the

lubricant

3. 3) The leaked liquid mixed with lubricant will corrode the bearings

inside pump

4. 4) Long time of shutdown will be required for replacing hose

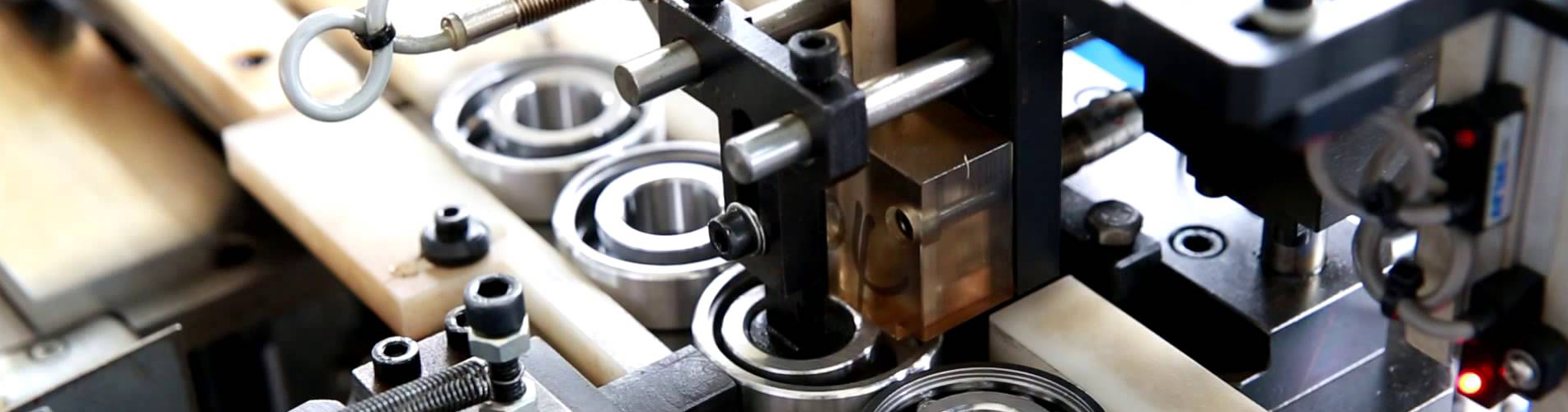

All our pumps are using roller to push the hose, assisted with NSK bearings,

there is no lubricant required. Even leak happened, there is no need to worry

about the contamination and it is very easy to replace hoses

categories

recent posts

copyright © 2026 Hefei Huayun Machinery Manufacturing Co., Ltd..all rights reserved. powered by dyyseo.com

ipv6 network supported